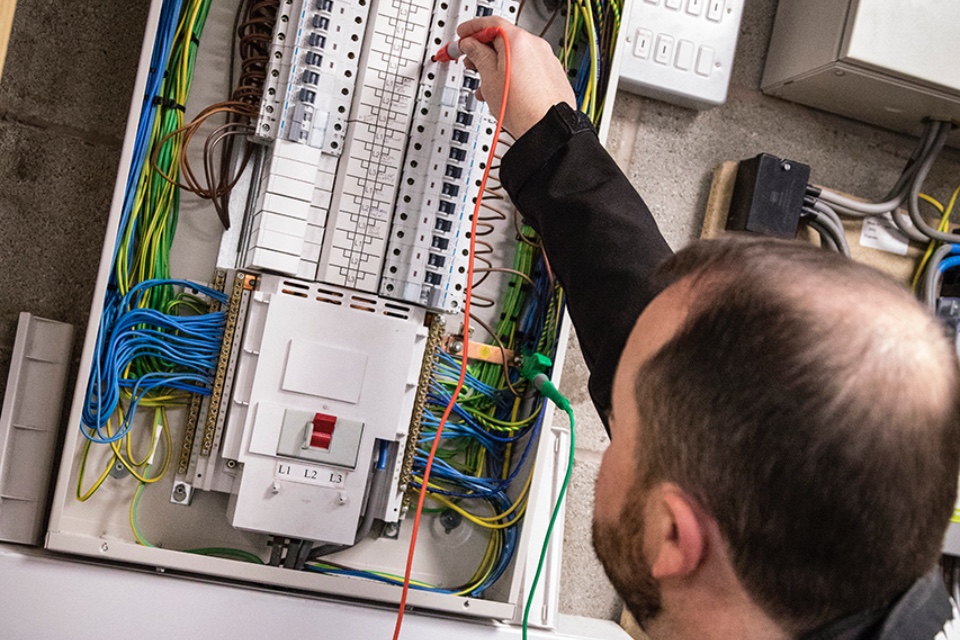

“Electrical testing is something that every single business has to do, regardless of current restrictions, but there is a lot of conflicting information about what electrical items need to be tested, and how often,” says Darren Blackbird, Sales Director at leading electrical testing and maintenance provider phs Compliance.

“The advice does not always take into account different types of business environments either, making it all the harder to ensure compliance.

“The Electricity at Work Regulations 1989 state that all electrical equipment in the workplace must be suitable for use and maintained to ensure it is safe. However, it does not specify how equipment should be maintained, how often it needs attention or who should carry out any maintenance, often leaving a question mark hanging over this important issue.

“Adding to the confusion is the misconception that you can simply delay or push back electrical testing because of the current pandemic, and that is leaving many businesses vulnerable. No-one wants to put their employees, their job or their business at risk.

“Generally, regular PAT testing and fixed wire testing are recommended by the experts as the best way to feel confident that you are meeting your legal obligations.

“PAT testing applies to portable electrical items, such as kettles, drills, laptops and computers, and fixed wire testing is relevant to fixed electrical installations, such as lighting or heating systems.

“The responsibility is placed on the duty holder to assess the risk level and decide on the frequency of inspections. This is usually determined by the type of equipment, how often it is being used and whether the working environment is considered high risk or low risk. Good practice is an annual test.

“For example, a drill used multiple times every day on a construction site will need more frequent inspections than a vacuum cleaner in a holiday let.

“Within BS 7671 it is recommended that electrical installations are tested everyone to five years, however this is dependant on the type of electrical installation, how often it is used and whether it’s in a low or high-risk environment. These frequencies are the maximum recommended, but again it is at the discretion of the duty holder and should depend on the type of electrical installation, how often it is used and whether it’s in a low or high-risk environment.

“Most offices require less frequent testing – once every five years, for example. However, a higher risk environment, like a swimming pool, which would be exposed to high levels of moisture, or an industrial unit with high dust levels, would require more frequent testing to ensure safety. This would more likely be everyone year for swimming pools and three years for industrial sites.

“It can be a minefield, which is why many businesses turn to a professional to ensure their equipment is correctly maintained. With expert advice, guidance and testing, they can feel confident that they are compliant.”

Click to view phs Compliance’s free PAT Testing Guide or Fixed Wire Testing Guide for further information.

With over 50 years’ experience, phs Compliance is one of the UK’s leading providers of facilities management and compliance services with over 400 engineers across the UK. As well as electrical, mechanical and fire safety testing and maintenance services, phs Compliance also provides specialist electrical and mechanical project services, including design, supply and installation for everything from power to lighting.