PRODUCT SPOTLIGHT: New Fixed RFID Reader and New Antenna GA25

The Brady FR22 Lite is the entry variant of the powerful Brady FR22 RFID reader. The FR22 Lite has the same RFID

The Brady FR22 Lite is the entry variant of the powerful Brady FR22 RFID reader. The FR22 Lite has the same RFID

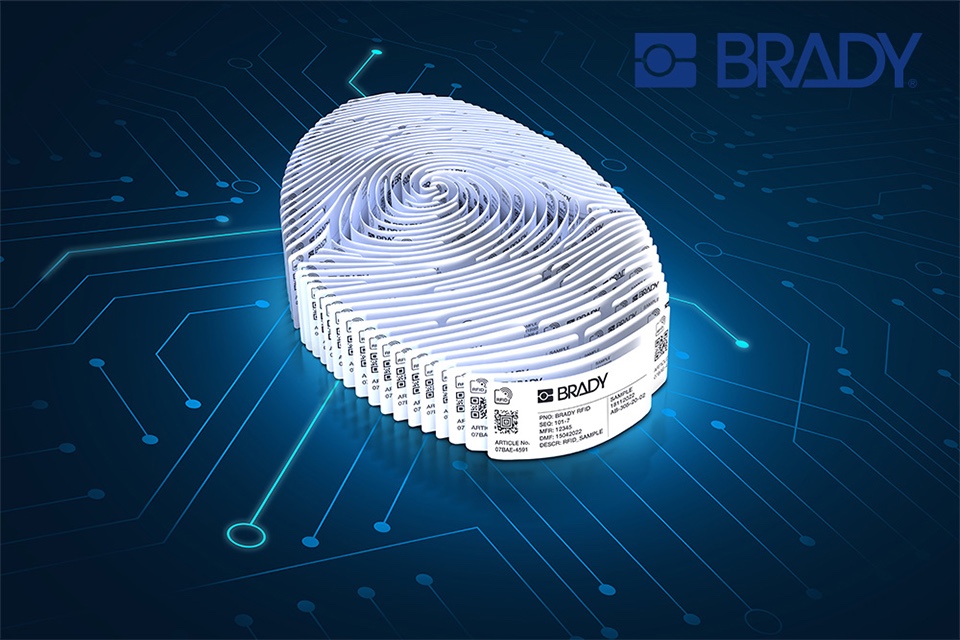

With Brady Corporation’s complete RFID solution, assets in any industrial environment can be given unique digital identities just by applying

…With reliable dual frequency UHF and NFC RFID labels from Brady Brady Corporation presents a new, highly reliable dual frequency

Facilities are among companies’ most important business assets, so are you still making the most of them? Are they maximised

Brady Corporation can design the optimal RFID labelling solution for asset tracking and inventory management that can fit any surface.

A very large chemicals processer increased the efficiency of asset safety inspections with inspection templates and automated reporting using reliable